Microfiltration – Ultrafiltration – Nanofiltration

Reverse Osmosis

2 October 2020

Filtration Technology

4 October 2020

Microfiltration

Microfiltration is a type of filtration physical process where a contaminated fluid is passed through a special pore-sized membrane (cartridge filter element) to separate microorganisms and suspended particles from process liquid. Cartridge filtration systems offer the benefits of filtration without the burdens of coagulant chemicals and settling basins that are associated with conventional filtration plants. The disadvantage, of course, is that cartridge filter elements require periodic replacement and for this reason they are most appropriate for relatively low-flow situations. Cartridges filter elements are manufactured from a number of materials, including cotton, nylon, polyester or polypropylene (similar to “felt”), nylon, carbon, and glass fibers. Filtration levels range from 100 microns down to 0.5 microns. Maximum flow rate is usually depending on the types of filters and the micron ratings selected.

Higher flow rates may be accommodated by placing multiple series of filters in parallel. A common arrangement for a series of cartridge filters is to place them in the order of decreasing micron size.

Ultrafiltration

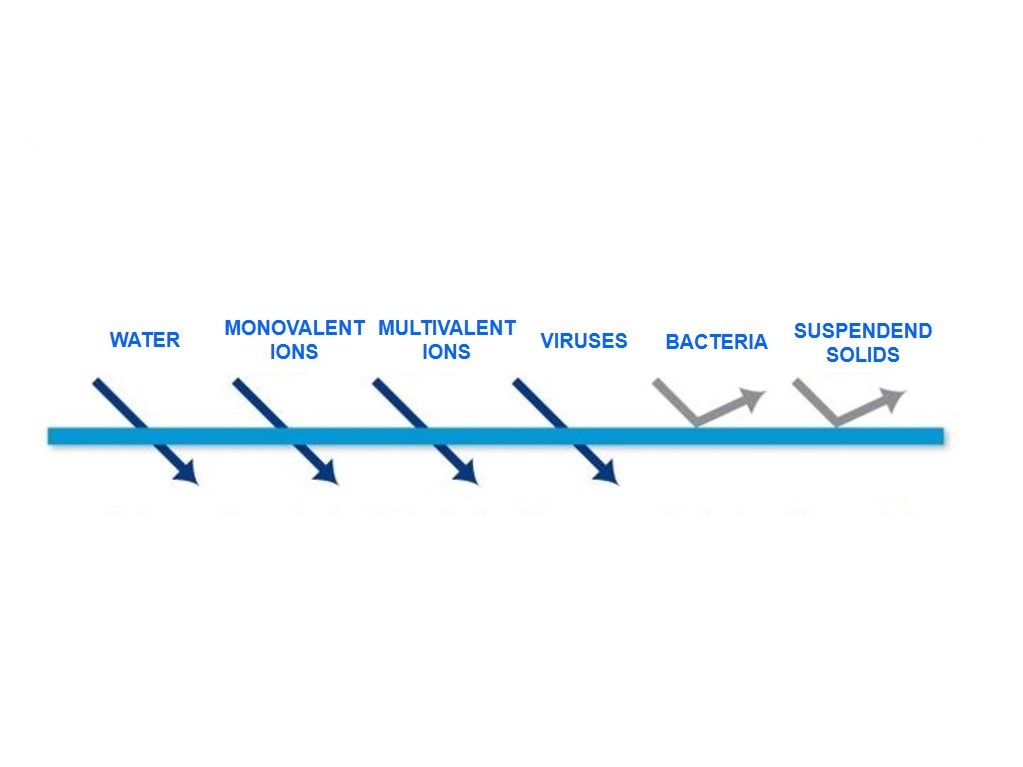

Ultrafiltration is a low- pressure driven membrane separation process that separates particulate matter from soluble components in the carrier fluid (such as water) at transmembrane pressures of, typically, 0.5 to 5 bars. UF membranes typically have pore sizes in the range of 0.01 - 0.10 µm and have a high removal capability for bacteria and most viruses, colloids and silt. The smaller the nominal pore size, the higher the removal capability.UF membranes can be fabricated essentially in one of two forms: tubular or flat sheet. Membranes of these designs are normally produced on a porous substrate material. The single operational unit into which membranes are engineered for use is referred to as a module. This operational unit consists of the membranes, pressure support structures, feed inlet, concentrate outlet ports, and permeate draw-off points.

Operation of UF membrane can be performed in two different service modes, i.e., dead-end flow and cross-flow. The dead-end flow mode of operation is similar to that of a cartridge filter where there is only a feed flow and filtrate flow.